Cold-rolled steel is an important material widely used in the industrial sector. It is a type of steel known for its flexibility, ease of processing, and relatively good corrosion resistance. Cold-rolled steel is manufactured through a specialized production and heat treatment process.

The following from the composition of cold rolled steel, production process, classification and application of several aspects.

Raw materials and alloy composition

Cold-rolled steel is typically made from primary materials such as iron and carbon. The alloy composition of cold-rolled steel can be adjusted to achieve the required properties, such as hardness, strength, and corrosion resistance.

The production process of cold-rolled steel

The production process for cold-rolled steel includes stages such as iron smelting, steelmaking, fabrication, and thin rolling. This process ensures the quality and uniformity of cold-rolled steel.

Processing and heat treatment in the manufacturing process

After cold-rolled steel is produced, it undergoes various processing and heat treatment steps to enhance its hardness and mechanical properties.

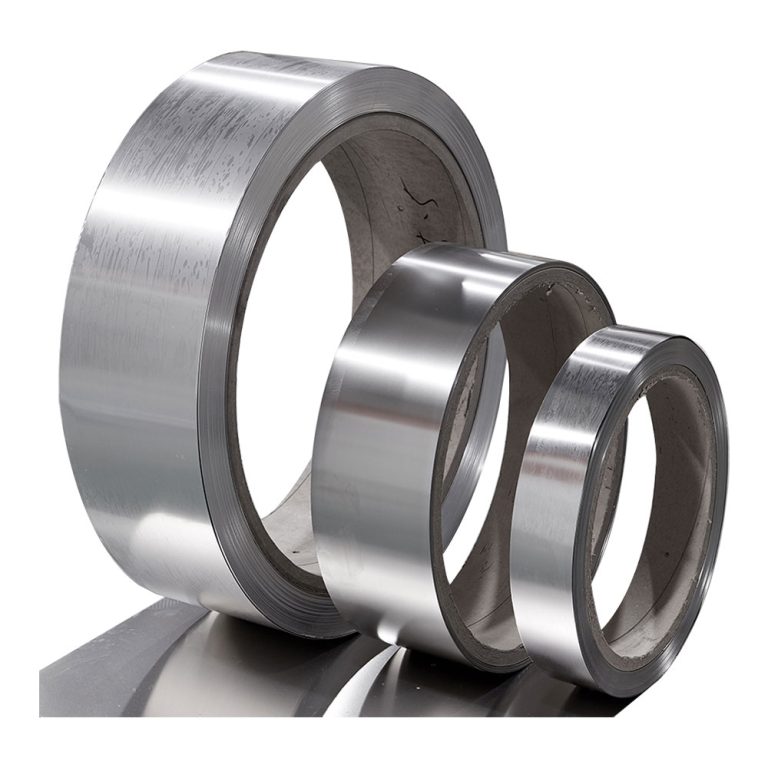

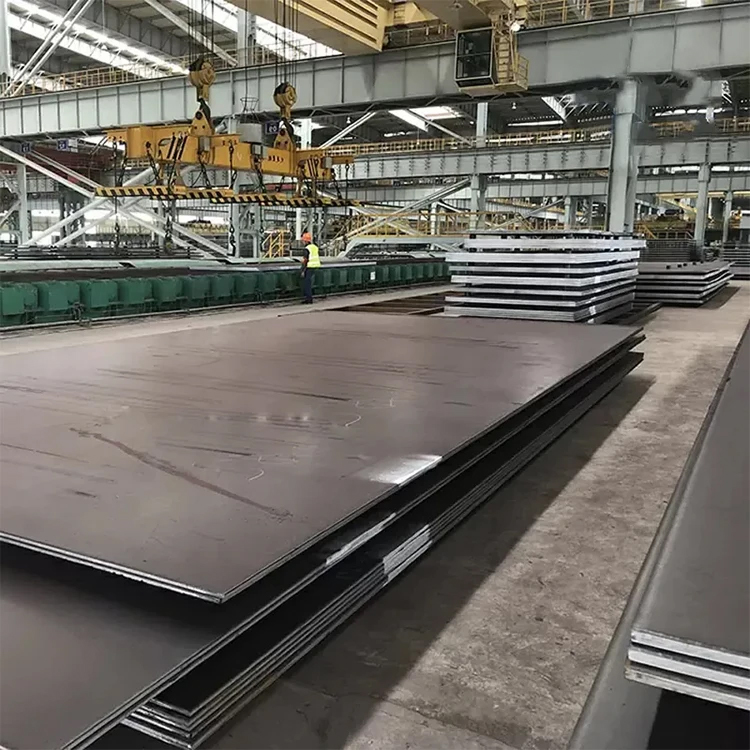

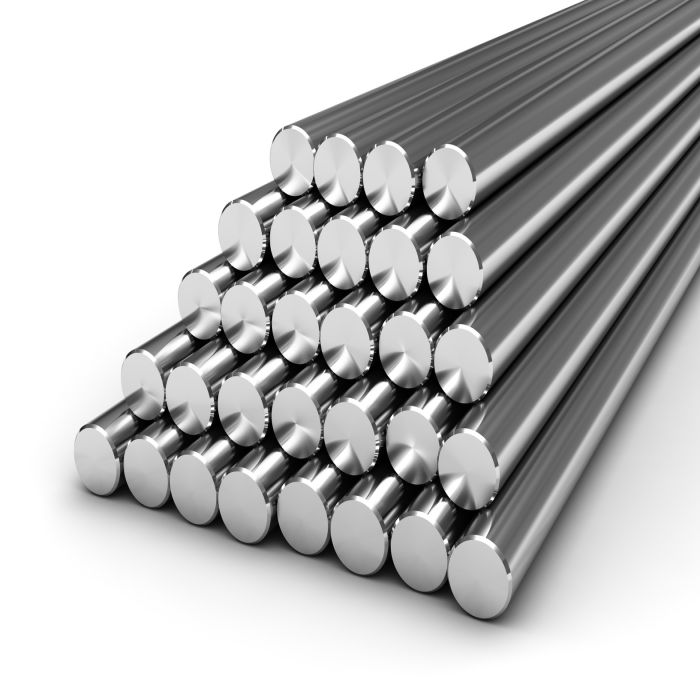

Classification of cold-rolled steel

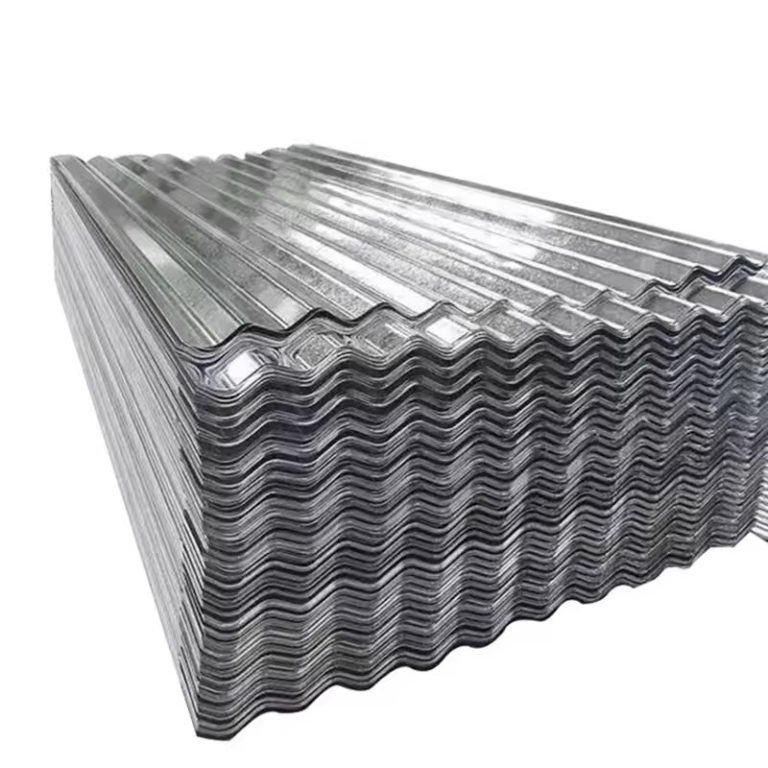

Mild Steel: Mild steel is a type of cold-rolled steel known for its high flexibility, ease of machining, and cost-effectiveness. It is commonly used in the construction industry, manufacturing of household appliances, and various other applications.

Stainless Steel: Stainless steel, a corrosion-resistant cold-rolled steel, finds extensive use in the food industry, healthcare, construction, and many other industrial sectors due to its high resistance to corrosion.

Alloy Steel: Alloy steel, a type of cold-rolled steel, is created by blending steel with other alloying elements such as nickel, chromium, manganese, and molybdenum. This type of steel exhibits special mechanical and structural properties and is used in applications that demand toughness and durability.

Applications of cold-rolled steel in daily life

Automotive and Transportation Industry: Cold-rolled steel is widely used in the production of automobiles and various modes of transportation, including cars, motorcycles, and trains. Its flexibility and durability meet stringent requirements in this industry.

Construction and Mechanical Industry: In the construction and mechanical sectors, cold-rolled steel is employed for structural purposes, building frames, water pipes, and various other applications. Its ease of machining and strength make it an ideal material for construction projects and machinery.

Electronics and Refrigeration Industry: Cold-rolled steel also plays a role in the electronics and refrigeration industry. It can be shaped into components such as pipes, screws, and other electronic accessories.

Conclusion

Cold rolled steel is an important material in the industrial sector with various applications. Through the production and heat treatment process, cold rolled steel can meet requirements for mechanical properties, load-bearing capacity, and corrosion resistance in many different fields. The development trend of the cold rolled steel industry focuses on advanced manufacturing technology and fabrication, as well as exploring new applications and potential developments in the areas of industrial and sustainable energy.