Prepainted aluminum plates have attracted great attention in various industries, so what are the advantages of Prepainted aluminum sheet?

What's the prepainted aluminum sheet?

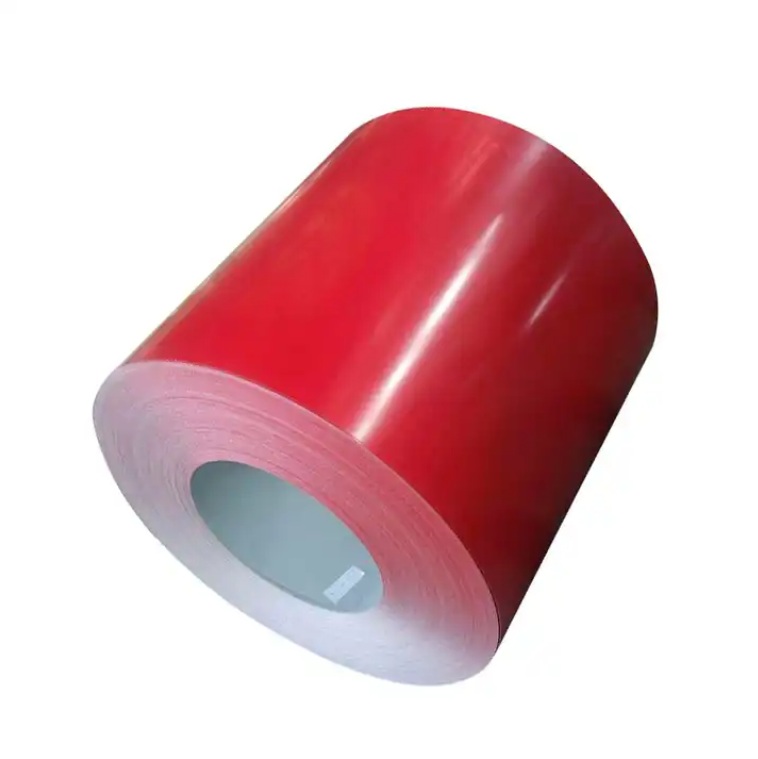

Prepainted Aluminum Sheet (Prepainted Aluminum Sheet) is an aluminum sheet that has been surface-coated before leaving the factory. This aluminum plate in the manufacturing process, first through cleaning, chemical treatment and other pretreatment steps, and then coated on the surface of one or more layers of paint, and finally after high temperature baking curing, forming a layer of solid, uniform coating. The pre-coated aluminum plate combines the light weight and corrosion resistance of aluminum and the decorative and protective coating, and is widely used in many fields such as construction, home appliances, and transportation.

The main features of pre-coated aluminum plate:

Aesthetics:

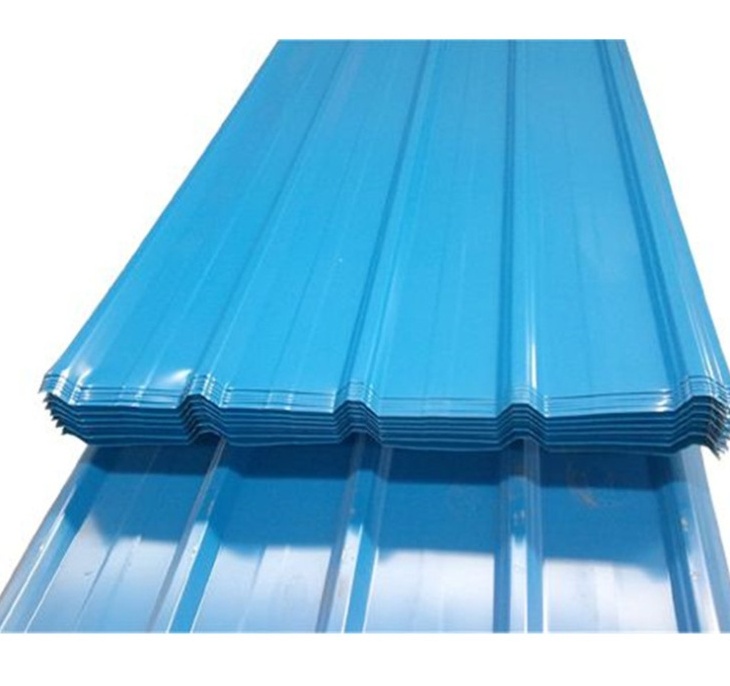

Prepainted aluminum sheets are available in a variety of colors, textures and glossiness to meet different design needs.

Uniform coating, bright color, can maintain the appearance of beauty for a long time.

Weather resistance:

The coating of the Prepainted aluminum sheet has excellent UV resistance, corrosion resistance and weather resistance, and can remain stable in harsh climatic conditions.

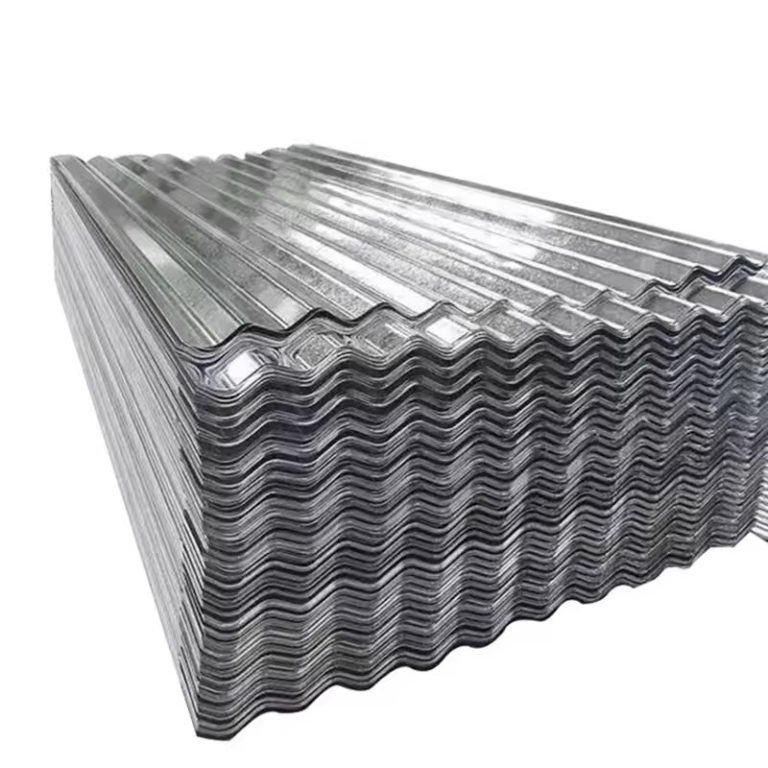

Suitable for outdoor building exterior walls, roofs and other scenes exposed to the natural environment.

Light weight and high strength:

The aluminum itself is light in weight but high in strength, and the pre-coated aluminum plate inherits this characteristic and is easy to transport and install.

It is especially suitable for high-rise buildings, large venues and other occasions where the weight of materials is strictly required.

Environmental protection:

The aluminum can be 100% recycled, and the production process of the Prepainted aluminum sheet also tends to use environmentally friendly coatings, in line with the concept of sustainable development.

The use of low VOC (volatile organic compounds) coatings reduces environmental pollution.

Machinability:

The pre-coated aluminum plate is easy to cut, bend, press and other processing, and can meet the design needs of various complex shapes.

Suitable for building curtain wall, interior decoration, home appliance shell and other applications.

Fire resistance:

Aluminum itself is a non-combustible material, and the pre-coated aluminum plate has good fire resistance and is suitable for places with high fire protection requirements.

Economy:

Although the initial cost of pre-coated aluminum is higher, its long life, low maintenance costs and energy saving characteristics make it more economical in long-term use.

Application areas of pre-coated aluminum plate:

Construction field:

Exterior wall decoration board, roof material, indoor ceiling, partition, etc.

Because of its light weight and weather resistance, it is particularly suitable for high-rise buildings and large public facilities.

Home appliance field:

The housing of refrigerators, washing machines, air conditioners and other household appliances.

The pre-coated aluminum plate is not only beautiful, but also can effectively protect the internal structure of home appliances.

Transportation:

Interior and exterior decorative panels for vehicles such as cars, trains and airplanes.

Lightweight features help reduce vehicle weight and improve fuel efficiency.

Advertising logo:

Used in the production of billboards, signs, etc., because of its rich color, strong durability.

Industrial Equipment:

Used in the manufacture of industrial equipment protective covers, shells, etc., to provide good protection and aesthetics.

Precoated aluminum sheet is a kind of high performance composite material, which combines the light weight and strength of aluminum and the decorative and protective coating. Its wide range of applications and excellent properties make it an important material in modern construction and manufacturing. Whether from the perspective of aesthetics, durability or environmental protection, Prepainted aluminum sheet is a quality material worth choosing.