You are probably well aware of the demanding environment of the chemical processing industry. Most chemical production processes have high temperature, high pressure, inflammable, explosive, toxic and corrosive conditions. Defects in design, material selection, manufacturing and maintenance of any link such as equipment, instruments, pipes and valves used in production will bring danger to production. At this point, it is necessary to choose materials that can withstand harsh conditions.

316 stainless steel applications in chemical processing

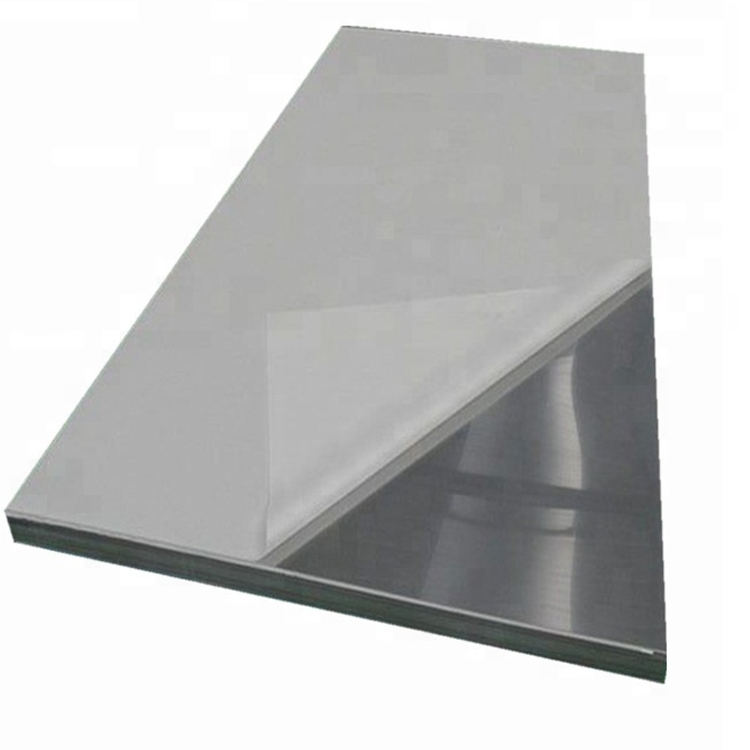

The versatility of 316 stainless steel makes them a go-to choice for various applications in the chemical processing industry.

From piping systems and vessels to reactors and other critical equipment, 316 stainless steel are widely used due to their exceptional durability and resistance to harsh environments.

In the petrochemical industry, 316 stainless steel are commonly employed in the production of gasoline, diesel, and other petroleum products, where they must withstand exposure to a range of chemicals and high temperatures.

Similarly, in the pharmaceutical industry, 316 stainless steel are used in the manufacturing of medications, ensuring strict adherence to sanitary standards and preventing contamination.

The fertilizer production industry, on the other hand, also relies heavily on 316 stainless steel due to their ability to resist the corrosive effects of various chemicals used in the manufacturing process.

In short, whether you're dealing with acids, bases, or aggressive gases, 316 stainless steel can provide the necessary protection and longevity for your equipment.

316 stainless steel has excellent durability and resistance, making it the ideal solution for your chemical processing needs.

Chemical composition of 316 stainless steel

| % | 316 | 316L | 316H | 316Ti |

| C | 0.0-0.07 | 0.0-0.03 | 0.04-0.08 | 0.0- 0.08 |

| Mn | 0.0-2.0 | 0.0-2.0 | 0.0-2.0 | 0.0-2.0 |

| Si | 0.0-1.0 | 0.0-1.0 | 0.0-1.0 | 0.0-1.0 |

| P | 0.0-0.05 | 0.0-0.05 | 0-0.04 | 0.0-0.05 |

| S | 0.0-0.02 | 0.0-0.02 | 0.0-0.02 | 0.0-0.03 |

| Cr | 16.50-18.50 | 16.50-18.50 | 16.50-18.50 | 16.50-18.50 |

| Mo | 2.00-2.50 | 2.00-2.50 | 2.00-2.50 | 2.00-2.50 |

| Ni | 10.00-13.00 | 10.00-13.00 | 10.00-13.00 | 10.50- 14.00 |

| Ti | - | - | - | 0.40- 0.70 |

| Fe | balance | balance | balance | balance |

Properties of 316 stainless steel

316 stainless steel, also known as austenitic stainless steel, is a highly specialized alloy with a unique composition that gives it superior properties.It contains molybdenum, which enhances its resistance to pitting and crevice corrosion, a critical factor when dealing with aggressive chemicals.

Additionally, 316 stainless steel boast a high strength-to-weight ratio and excellent mechanical properties, ensuring they can withstand the rigors of chemical processing environments.

Corrosion Resistance of 316 stainless steel

Stainless steel 316 has excellent corrosion resistance when exposed to a range of corrosive environments and media. It is usually regarded as “marine grade” stainless steel but is not resistant to warm sea water. Warm chloride environments can cause pitting and crevice corrosion. Grade 316 is also subject to stress corrosion cracking above around 60°C.

Heat Resistance of 316 stainless steel

316 stainless steel has good resistance to oxidation in intermittent service to 870°C and in continuous service to 925°C. However, continuous use at 425-860°C is not recommended if corrosion resistance in water is required. In this instance 316L is recommended due to its resistance to carbide precipitation.

Where high strength is required at temperatures above 500°C, grade 316H is recommended.

Henan Zhencang Steel Co., Ltd. stocks Stainless steel in a range of sizes. Stainless steel Material of alloy can be supplied in random lengths, cut to order or machined to customer's specifications. We provide tailored solutions that meet specific material specifications, To buy or learn more about stainless steel contact us now, we will be in touch shortly.